Theoretical Study for Tailings Stacks Maximum Height Evaluation

Sylvia de Jesús1, Luana Schulz2, Thiago Souza2, Isabella de Souza1, Anselmo Mendes1, Sálefe Xavier1, Nilthson Noreña1, Alessandra Teixeira¹ and Washington Silva2

- Vale, Brazil

- BVP, Brazil

ABSTRACT

The mining industry is shifting towards dry stacking for tailings disposal, focusing on minimizing risks of geotechnical structure failures. Designing dry stacks requires a thorough understanding of the diverse physical and geotechnical properties of iron ore tailings. Furthermore, the demand for increased iron ore production, alongside with limited construction space, often leads to the need for large dry stacks. This paper analyzes laboratory test data from tailings in the Quadrilátero Ferrífero region. It evaluates their physical characteristics and geotechnical behaviors, specifically determining critical state parameters to calibrate the NorSand model. This model is used to predict how different operational void ratios behave under simulated high stress levels, ultimately helping to estimate the maximum safe height for filtered tailings stacks across various tailings categories.

INTRODUCTION

The current drive of the mining industry is prioritizing tailings dry stacking over dams on what concerns tailings disposal, following Principle 5 of the Global Industry Standard on Tailings Management – GISTM (ICMM, 2020). This regards the development of designs that minimize the risk of failure of geotechnical structures to people and the environment.

Parallel to the GISTM principles, the diversity of the iron ore tailings, which arises from the different beneficiation processes, must be considered in geotechnical structures designing. This implies in a variety of physical and geotechnical tailings properties, which should be evaluated in terms of mechanical behavior as to ensure structural safety of the stacks.

Additionally, the requirements to meet iron ore production, together with area restrictions for construction, can result in the need of stacks of large magnitude, that often exceed 100 m in height, and depending on disposal conditions, the stacks could be susceptible to liquefaction. This reinforces the importance of robust design guidelines based on the behavior of material under high stress level.

In this paper, data from laboratory tests in the Quadrilátero Ferrífero tailings are analyzed, and their physical characteristics and geotechnical behaviors are evaluated. The critical state parameters are determined as to calibrate the NorSand model for the prediction of different operational void ratio values for simulated high stress levels to estimate a maximum height of filtered tailings stacks for different categories of tailings.

METHODOLOGY

An extensive database of physical characterization and laboratory tests for different types of tailings from iron ore beneficiation plants in the Quadrilátero Ferrífero, Minas Gerais, Brazil, was provided. This allowed two stages of study: tailings categorization and mechanical behavior evaluation.

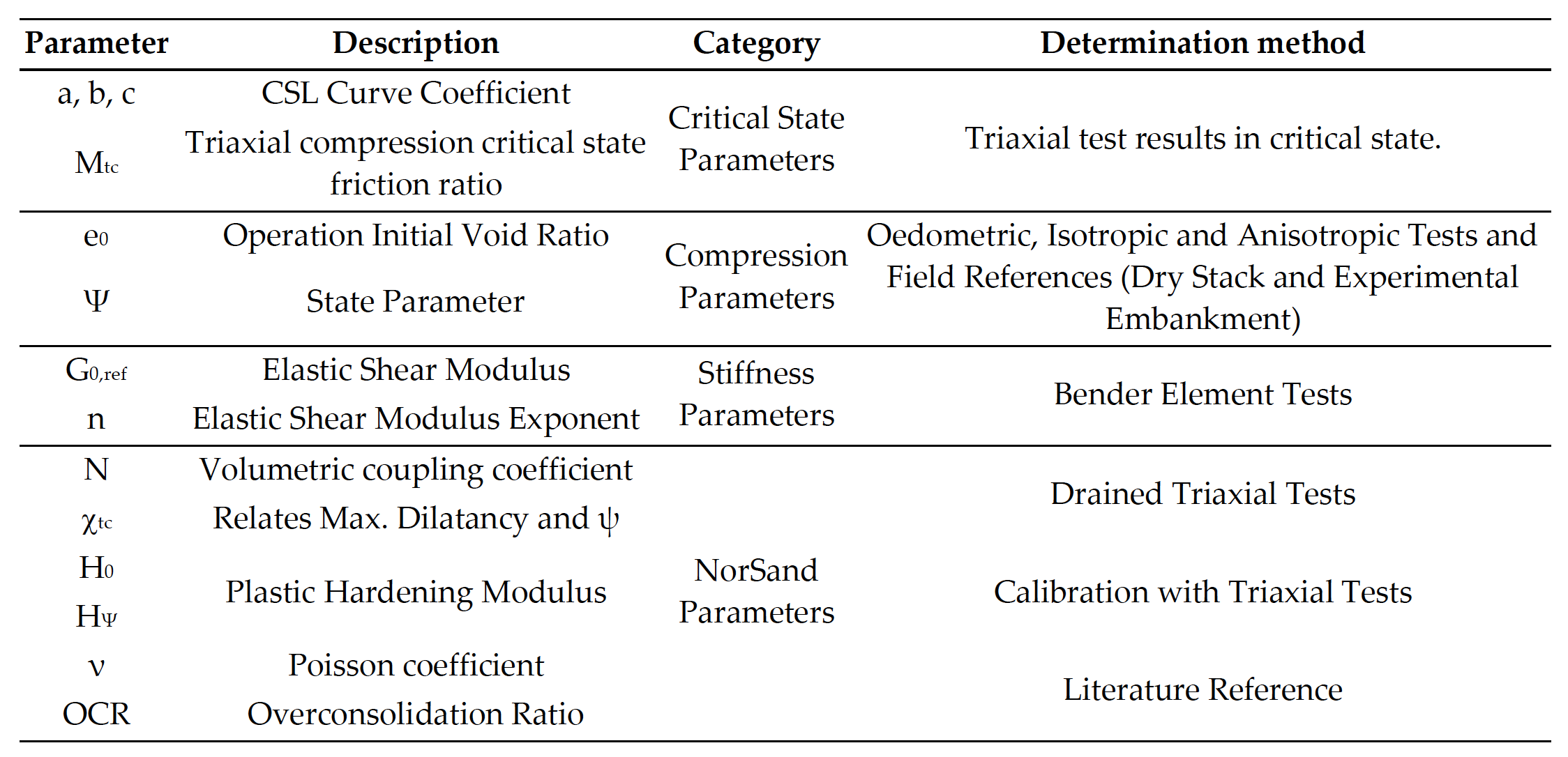

The categories of tailings were defined using granulometry, solids specific mass and triaxial test results. The data was evaluated and processed for more than 300 tested samples, with elimination of outliers and scattered information. The results were organized in graphics, establishing four tailings categories considering the evaluated mechanical behavior and its similarities: sandy tailings, mixtures 90/10, 80/20 and 70/30 (being the lower number correspondent to the fine content proportion of the sample, diameter smaller than 10 µm). The granulometry and mechanical behavior similarities of tailings enabled the parametrization of a Critical State Line (CSL) for each tailings category.

The NorSand model (Jefferies & Been, 2016; Shuttle & Jefferies, 2010) was selected for the calibration of the shear response of the different categories of tailings, simulating operation of tailings dry stacking in different initial void ratio values and confinement conditions. This model accurately portrays the geomechanical behavior of non-plastic silts and sands – adequate for the representation of tailings with lower ultrafine fraction.

The absence of a parameter correlating the limit compression line and the initial state of the material and the Hardening Law uncoupled from the initial state of the material are known limitations for the Norsand model. Nonetheless, the Norsand representativeness for tailings is well established in literature and suitable for the conduction of this study.

The parameters required for the calibration of the model and their process of determination are presented in Table 1 (Jefferies & Been, 2016; Viana da Fonseca et al., 2021).

Table 1 Summary of the employed parameters.

RESULTS AND DISCUSSION

The tailings categories were defined according to granulometry, and typical values of γs, which lead to the definition of friction ratio (Mtc) and Critical State Lines (CSL), shown in Figure 1. The CSL equations were parametrized with the adjustment of the a, b and c coefficients (Verdugo, 1992).

The increase in ultrafine fraction (diameter smaller than 10 µm) implies on lower final void ratio in the consolidation tests, and the CSL becomes lower due to the compaction of the grains of the tailings. Given the samples mineralogy is similar, Mtc presented less variability (1,32 a 1,42), as expected.

Figure 1 Critical State Lines abacus (CSLs, Mtc, Granulometric Ranges e γs)

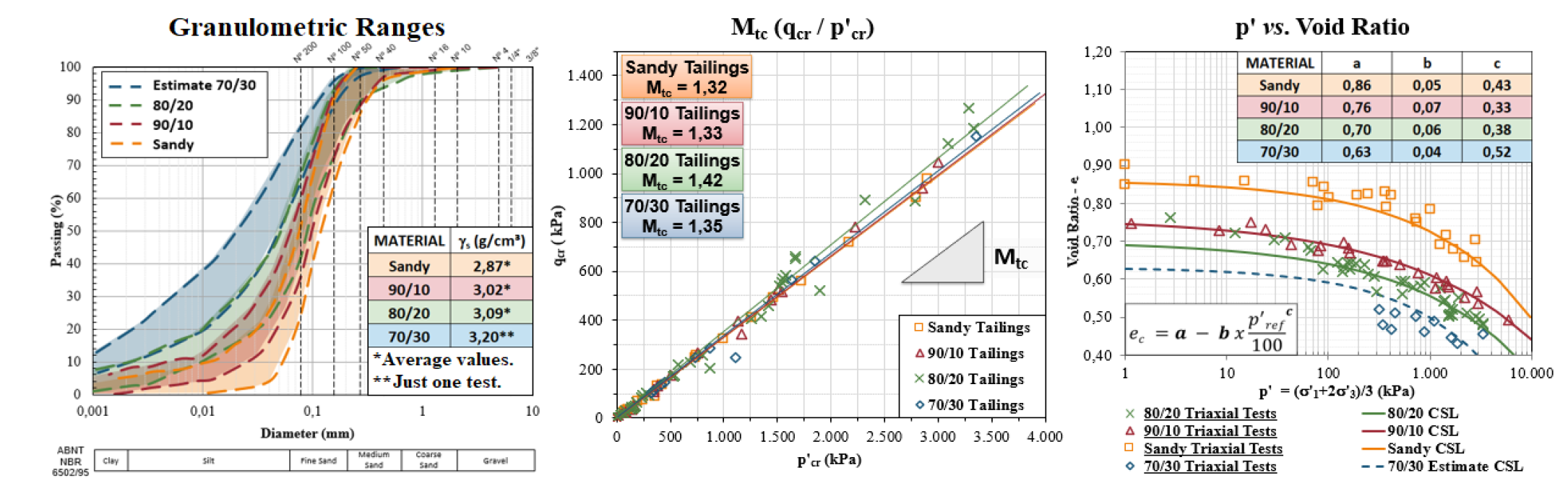

The results of the oedometric, isotropic and anisotropic consolidation tests show that the different tailings categories behave correspondingly in compression condition for similar void ratio, implicating in similar shape for the curves regardless of the tailings category (Figure 2a).

The reference compression curves were defined for specific initial void ratio values, considering operational conditions and experimental embankments. When the compression curves for each void ratio are plotted with the CSL for each tailings category, the state parameter is positive as confinement increases – medium to high stress levels (Figure 2b). This highlights that even with tailings compaction, it is important to evaluate the mechanical behavior in terms of the critical state, as dense materials can achieve positive state parameters depending on confinement and stress conditions.

As tailings become denser as confinement increases, it is also expected an increase in its initial stiffness. This can be observed in the results of the bender element tests under different confinement stress levels. In Figure 2c, the Elastic Shear Modulus equations are presented.

Figure 2 (a) (b) Compressibility curves for the tailings categories and state parameter change indication; c) Elastic shear modulus (G0 and n)

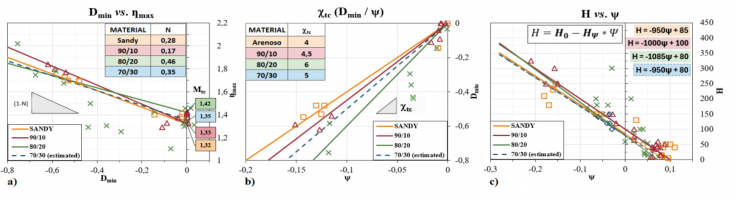

The results of parameter N are presented in Figure 3a. The volumetric coupling method values follow the order of magnitude observed in literature, and adequate to the value of M previously defined (Figure 1). For the 70/30 mixture, the median of typical values for sands was considered (0,35), as suggested by Jefferies & Been (2016), due to the lack of drained triaxial test results for this category.

The values of χtc are presented in Figure 3b. They were obtained with consolidated, isotropic, drained (CID) tests for dense and loose samples for sandy tailings, mixture 90/10, and mixture 80/20. For the mixture 70/30, the value of χtc was defined as 5,0, to fit adequately to the other categories and within the typical range value of sands (Jefferies & Been, 2016).

The evaluation of the plastic hardening modulus (Figure 3c) shows similar values for the categories, with adequate convergence of the test results during calibration. For the mixture 70/30, the values of H0 e HΨ were adjusted to 80 and 950 given the limited number of tests and considering the lowest values of the other categories.

Figure 3 a) Volumetric coupling, N; b) Dilatancy (Dmin) and State Parameter (Ψ) ratio, χtc; c) Plastic hardening modulus for the different tailings categories

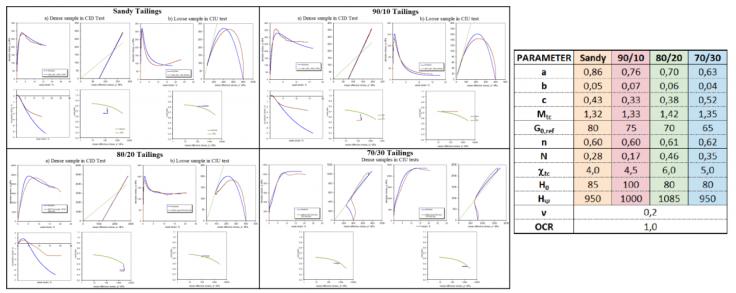

Based on the parameters presented in the previous sections, and considering the overconsolidation ratio (OCR) as 1, and Poisson coefficient (ν) as 0,2, it was possible to obtain a satisfactory calibration for the four tailings categories. The Norsand model adjusted to the tailings categories and the values of the calibrated parameters are presented in Figure 4.

Figure 4 Calibrated parameters for the tailings categories

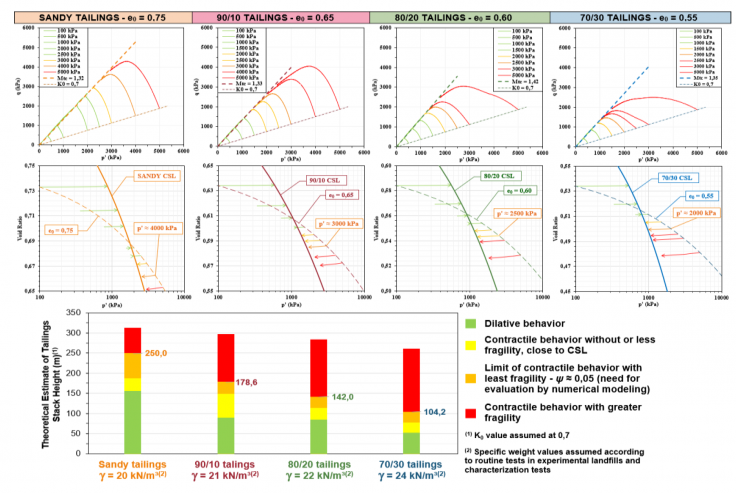

The result of the simulation of the shear responses of the four categories of tailings using the NorSand model is presented in Figure 5.

Figure 5 Shear response simulation for each tailings category and theoretical estimate for tailings stack height

The simulation condition considers an operational void ratio value for each category, and stress levels simulating the compaction of the tailings layers, with anisotropic consolidation initial condition and K₀ = 0,7. Four different typical behavior patterns were identified, and a color was addressed to each of them to associate to the risk of failure:

- Green: predominant dilative behavior – adequate behavior for tailings stacking.

- Yellow: transition between contractile and dilative behavior, with state parameter close to zero and low fragility, the limit for tailings stacking.

- Orange: state parameters close to 0,05. Specific numerical modeling is recommended for these stress levels.

- Red: contractile behavior, which requires additional evaluation via numerical modeling, and possibly requires material disposal exclusively under confined conditions.

The estimated reference height values represent specific compaction conditions for each tailings category, and any variation in the initial void ratio influences the result. In a comprehensive approach, void ratio and fines content are inversely proportional to the maximum height of the stacks: the maximum admissible stress level is larger for smaller fines content and void ratio.

CONCLUSION

The analysis of the four tailings categories allowed not only the theoretical estimate of tailings stacks maximum height, but also the identification of the geotechnical behavior pattern. Tailings with sandy

characteristics tend to present a wider range of void ratio with dilative behavior (left of the CSL). On the other hand, finer tailings are more limited, and more likely to contractile behavior.

State parameter values close slightly positively (around 0,02) or closer to zero can still imply in dilative response. However, under these conditions, a safety margin must be considered due to the variability of the materials. Finally, contractile behavior with a larger risk of liquefaction should be avoided under the observed conditions. In these cases, complementary numerical analyses are essential to guarantee stability considering different failure mode triggers.

ACKNOWLEDGEMENTS

The authors express their gratitude to Vale S/A for the support provided to the project, carried out in collaboration with BVP Geotechnical and Hydraulic Engineering. The views expressed in this article are those of the authors and do not necessarily represent the position of the mining company.

REFERENCES

International Council on Mining and Metals – ICMM (2020). Global Industry Standard on Tailings Management.

United Nations Environment Programme, Principles for Responsible Investment, London.

Jefferies, M., Been, K. (2016). Soil liquefaction: a critical state approach, 2nd Edition, CRC Press, Boca Raton, FL, USA.

Shuttle, D., & Jefferies, M. (2010). ‘NorSand: description, calibration, validation and applications’. Geo-Frontiers Conference 2005: Soil Constitutive Models: Evaluation, Selection, and Calibration, ASCE, Austin, TX, p. 1-31.

Verdugo, R. (1992) ‘The critical state of sands: Discussion’. Géotechnique, Volume 42, Issue 4, p. 655–663.

Viana da Fonseca, A.; Cordeiro, D.; Molina-Gómez, F. (2021) ‘Recommended Procedures to Assess Critical State

Locus from Triaxial Tests in Cohesionless Remoulded Samples’. Geotechnics, Vol. 1, Issue 1, p. 95-127.