Abstract

Due to regulatory policies that prohibit raising dams upstream in Brazil, research studies on alternative methods of disposal of filtered tailings in mining activities have been conducted in various mining companies, particularly in iron ore mines in the Iron Quadrangle. The objective of these studies is to reduce the need for slurry tailings disposal in dams, thereby minimizing the associated risks of downstream damage to tailings structures These studies involve experimental landfill tests to understand the behavior of compacted tailings and provide geotechnical parameters for design of Dry Stacking Tailings.

This paper presents the experiences obtained from the experimental landfill tests involving a mixture of filtered iron ore tailings (sandy and ultrafine mixtures). The study includes an evaluation of compaction performance by applying different energy variations, layer thicknesses and moisture content, as well as an analysis of the variabilities in physical characteristics and compaction curves of the tested iron ore tailings mixtures from Iron Quadrangle mines.

Introduction

For the disposal of tailings mixtures (sandy and ultrafine), a profound understanding of field compaction behavior is crucial to ensure optimal layer performance. In this context, in the experimental landfill tests of filtered tailings, referred to in this study as partial tailings (characterized by a composition of approximately 90% sandy and 10% ultrafine, by mass) and total tailings (characterized by a composition of approximately 80% sandy and 10% ultrafine, by mass), variations in moisture content representing operations during dry and wet seasons were tested. Additionally, variations in compaction energy (number of roller passes and vibration) and layer thicknesses were investigated.

The compaction performance results from the experimental landfill tests of the partial and total filtered tailings mixture were consolidated and interpreted to provide an integrated analysis of the mixtures. This analysis focused on behaviors related to void ratio reduction and variations in degree of saturation after compaction. Moisture content varied within the target range (close to optimum), as well as both below and above the target moisture range

Methodology

The production of partial (90/10) and total (80/20) filtered tailings was achieved by incorporating ultrafine particles into the sandy tailings. In this process, the tailings generated from iron ore beneficiation are pumped to conditioners that supply a battery of hydrocyclones. These hydrocyclones separate the denser and coarser fractions (underflow) from the less dense and finer fractions (overflow) of the tailings.

The overflow stream from the cyclones proceeds to the slurry thickener, which also receives the filtered water from the tailings disc filtration system. The water resulting from the thickening process of the overflow is directed to a tailings dam, while the thickened material (ultrafine particles) is combined with the underflow from the cyclones (sandy tailings) for mixing in a conditioner. Subsequently, the mixture is fed into the disc filtration system, and the resulting filtered total tailings are directed to the experimental landfills. The unit filtration rate of the disk filter used in the experimental tests was 2.27 t/h/m3 for partial tailings (90/10) and 1.53 t/h/m3 for total tailings (80/20).

To assess the mechanical behavior of the filtered tailings, compaction was conducted using a smooth 20-ton roller (with and without vibration), as depicted in Figure 1a, b. Various layer thicknesses (30 cm, 50 cm, 70 cm, and 100 cm) and moisture contents (wet branch, dry branch, and near-optimal moisture content) were varied.

Figure 1: Compaction with a 20ton smooth roller of tailings mix (a) and sandy tailings (b)

Throughout the experimental tests, disturbed samples were collected for the purpose of conducting characterization tests, particle size analysis through sieving and sedimentation, following the guidelines of NBR 7181 (ABNT, 2018), as well as Proctor compaction tests according to NBR 7182 (ABNT, 2016).

For the evaluation of the compaction behavior of the tailings, the determination of in-situ bulk density was carried out using a drive cylinder, in accordance with the guidelines outlined in NBR 9813 (ABNT, 2016). The degree of compaction was determined using the Hilf Method – NBR 12102 (ABNT, 2020) – and subsequently confirmed through Proctor Compaction. Furthermore, the moisture content of the layers after compaction, void ratio, and degree of saturation were also examined.

Physical Characteristics and Compaction Curves of Filtered Tailings

In general, the characteristics of the filtered tailings are influenced by the raw ore and the industrial process used in beneficiation (Araújo, 2006; Ghose and Sen, 2001), for example, according Srivastava et al. (2001) an iron ore with a high clay content and which is softer generates more fine particles during mineral processing, which is reflected in the material’s particle size curve.

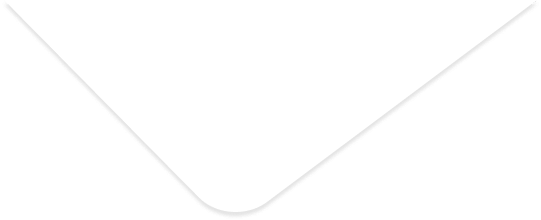

Figure 2a, b depicts the grain size distribution curves of the tailing’s mixtures and the sandy tailings material tested, as well as the compaction curves for the three tested tailings typologies.

Figure 2: Particle size curves (a) and compaction curves of the tailings tested (b)

Figure 2: Particle size curves (a) and compaction curves of the tailings tested (b)

From the analysis of Figures 2a, there is an observed differentiation in the fine fraction of the tested tailings (below the #200 sieve), with notable percentages passing through 10μ and 45μ sieves, which are as follows:

- Sandy Tailings: Percentage passing through 10μ varied between 3% and 8%, and through 45μ ranged from 12% to 25%.

- 90/10 Tailings: Percentage passing through 10μ varied between 6% and 12%, and through 45μ ranged from 19% to 38%.

- 80/20 Tailings: Percentage passing through 10μ varied between 10% and 18%, and through 45μ varied from 25% to 45%.

Regarding the maximum dry densities and optimal moisture content obtained for the tailing’s mixture (Fig. 2b), in comparison to the tailings without the addition of ultrafine, the following observations can be made:

- Tailings mixtures are more sensitive to variations in moisture content. Because of it, it’s important to compact the tailings mixtures according to the ” target Moisture Range ” established in the “Base Case” in order to guarantee adequate compaction performance;

- Higher maximum Dry Density with the addition of ultrafine: This effect can be attributed to the concentration of iron fines in the ultrafine, which have a higher density than sandy tailings (approximately 3.6 to 3.9 g/cm³) with an increase in gs of the material;

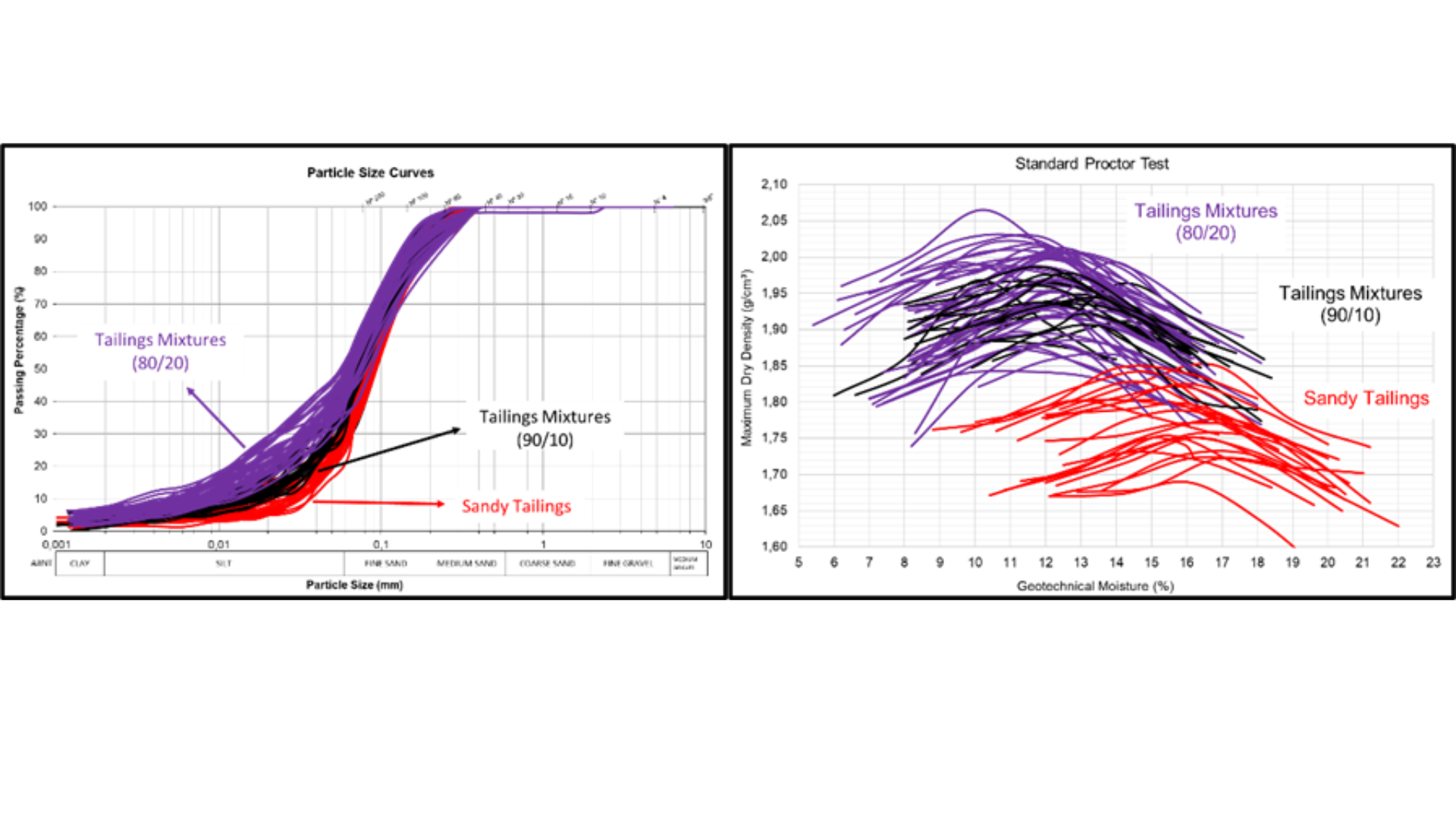

- Lower Optimal Moisture Content with the addition of ultrafine: This effect can be attributed to greater packing of the tailing’s mixtures, since the ultrafine fines occupy the empty spaces in the sandy matrix, reducing the amount of water needed to achieve maximum densification of the partial and total tailings, to the detriment of the sandy one. Figure 3 shows the optimum moisture variation as a function of the percentage of fines passing through 10m.

Figure 3: Optimum humidity vs percentage passing in 10 m

Figure 3: Optimum humidity vs percentage passing in 10 m

The coefficients of uniformity (CU) and curvature (CC) of the tailing’s mixtures tested, as well as the tailings without the addition of ultrafine, were obtained based on the particle size distributions of the materials. Table 1 shows the average CU and CC values for each type of tailings tested in the landfill.

Table 1 – Variation ranges of the Coefficients of Uniformity and Curvature of the Tailings Tested

| Sample | Coefficient of Uniformity (CU) | Coefficient of Curvature (CC) |

| Sandy Tailings | 3,8 | 1,4 |

| 90/10 Tailings | 6,5 | 1,9 |

| 80/20 Tailings | 11,4 | 2,1 |

From the comparative analysis of the coefficients of uniformity (CU) among the tailings types, there is an indication that in the sandy tailings, particle diameters are more similar when compared to the total and partial tailings, resulting in a lower coefficient of uniformity (CU<6).

Therefore, for the amount of fines used in experiments, it is suggested that the addition of ultrafine material to the sandy matrix contributes to a better particle size distribution of the material. This means that the spaces left by larger particles are filled by the smaller particles of the ultrafine tailings, promoting an improvement in the packing and interlocking condition of particles (partial fitting between adjacent particles). This leads to increased strength and reduced compressibility of the material when compacted close to the optimum moisture content.

Base Case Composition of Tailings Mixtures

Based on the interpretation of the tests conducted on the tested tailings in the experimental landfills, it was observed for both the partial tailings and the total tailings, a variability in the particle size distribution and compaction curves that represent each tailings typology. It was not possible to perform a test with a specific control that would accurately represent the exact proportion of a mixture.

This variability is linked to various operational causes, varying according to the type of ore processed in the plant or the influence on the filtering process, such as flocculant dosages, control of the proportion of ultrafine mass in the mixture, as in this case, as well as control of the pulp density in the disc filter feed.

Even though there were observed differences in particle sizes between the partial and total tailings, an overlap in optimal compaction densities and moisture content was noticeable, leading to similar compaction performance when compacted close to the target moisture levels.

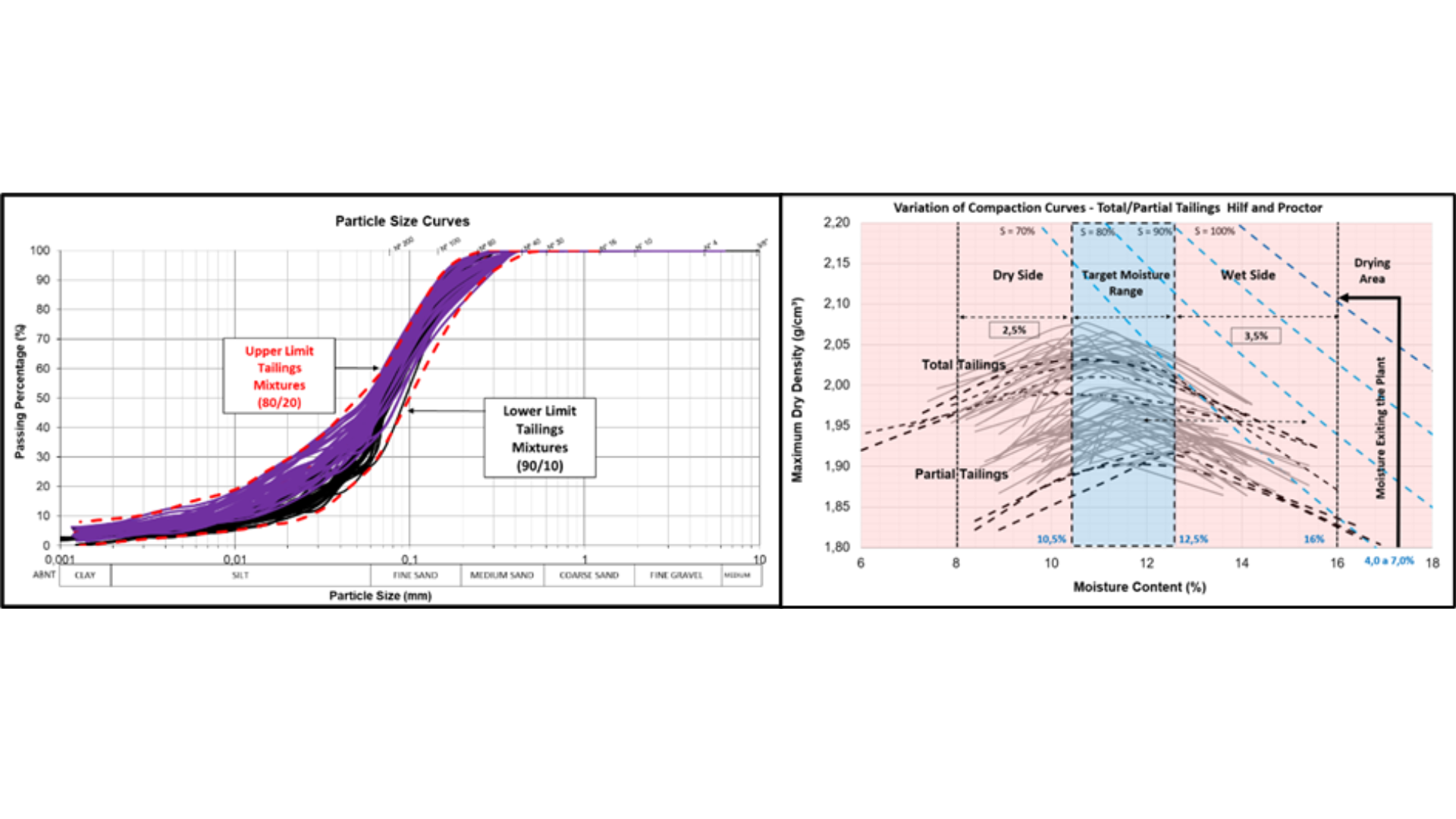

Therefore, in a scenario where controlling a specific mixture type was challenging, an approach was taken to address the variations in tailings mixtures. This approach aimed to represent the material generated by the plant and incorporated mixture proportions ranging from 90/10 to 80/20, forming what is referred to as the “Base Case”.

In addition to the delineation of granulometric limits, a treatment of the unified compaction curves of the tested tailings was also proposed, with a target moisture content for compaction being defined, resulting in degrees of saturation below 80%, void ratios below 0.60, and a degree of compaction above 95%, seeking to obtain the material’s expansion behavior. Thus, for moisture control in tailings disposal, limits were identified between 10.5% and 12.5%. The granulometric limits and the desired humidity thresholds are shown in Figure 4a, b.

Figure 4: Base Case Grain Size Limits(a) Target moisture ranges for compaction (b)

As can be observed in Figure 4, several crucial pieces of information are interpreted and established as construction controls for achieving proper compaction performance and consequently low void ratios and low degrees of saturation below 80%. The key points are outlined as follows:

- Target moisture range: Moisture variation between 10.5% and 12.5%, interpreted as optimal compaction performance for both partial and total tailings (Base Case);

- Wet branch moisture range: Moisture variation between 12.5% and 16%, interpreted as moderate compaction performance for both partial and total tailings (baseline case), with the presence of “borrachudo” (a term often used in Brazilian mining for sticky, plastic clay-like materials);

- Dry branch moisture range: Moisture variation between 8% and 10.5%, interpreted as moderate compaction performance for both partial and total tailings (Base Case), requiring vibration for enhanced performance.

Thus, it can be observed that the compaction performance of the tailings mixtures in the field relies primarily on pre-compaction moisture control, avoiding reworking of layers due to inadequate compaction performance, as well as the effects of rubberization or water exudation.

The study then proceeds with an analysis of the compaction performance of the layers within the target moisture range, comparing them to the results of layers compacted in the wet and dry ranges. This analysis examines key technological controls such as in-situ dry density, void ratio, and degree of saturation.

Compaction performance as a function of field energies and moisture ranges

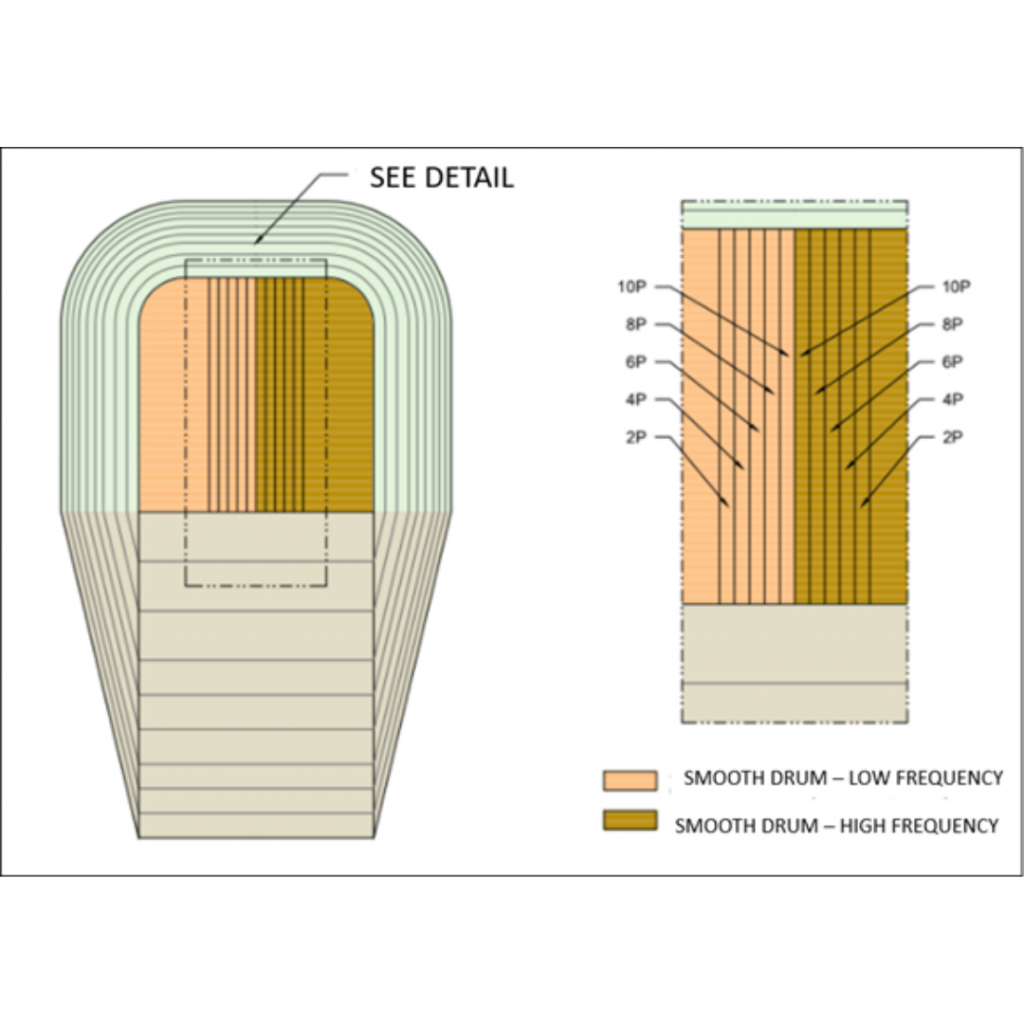

Regarding the compaction performance, the analyses were conducted with a focus on referencing the results obtained from Standard Proctor Tests. In total, 12 layers were constructed, varying in thickness, compaction energy (number of passes with and without vibration), and moisture content (dry, wet, and target for compaction). Figure 5 displays the layout of tracks within the experimental landfill. Figure 5: Layout of the experimental landfill: variation of energies and number of passes

Figure 5: Layout of the experimental landfill: variation of energies and number of passes

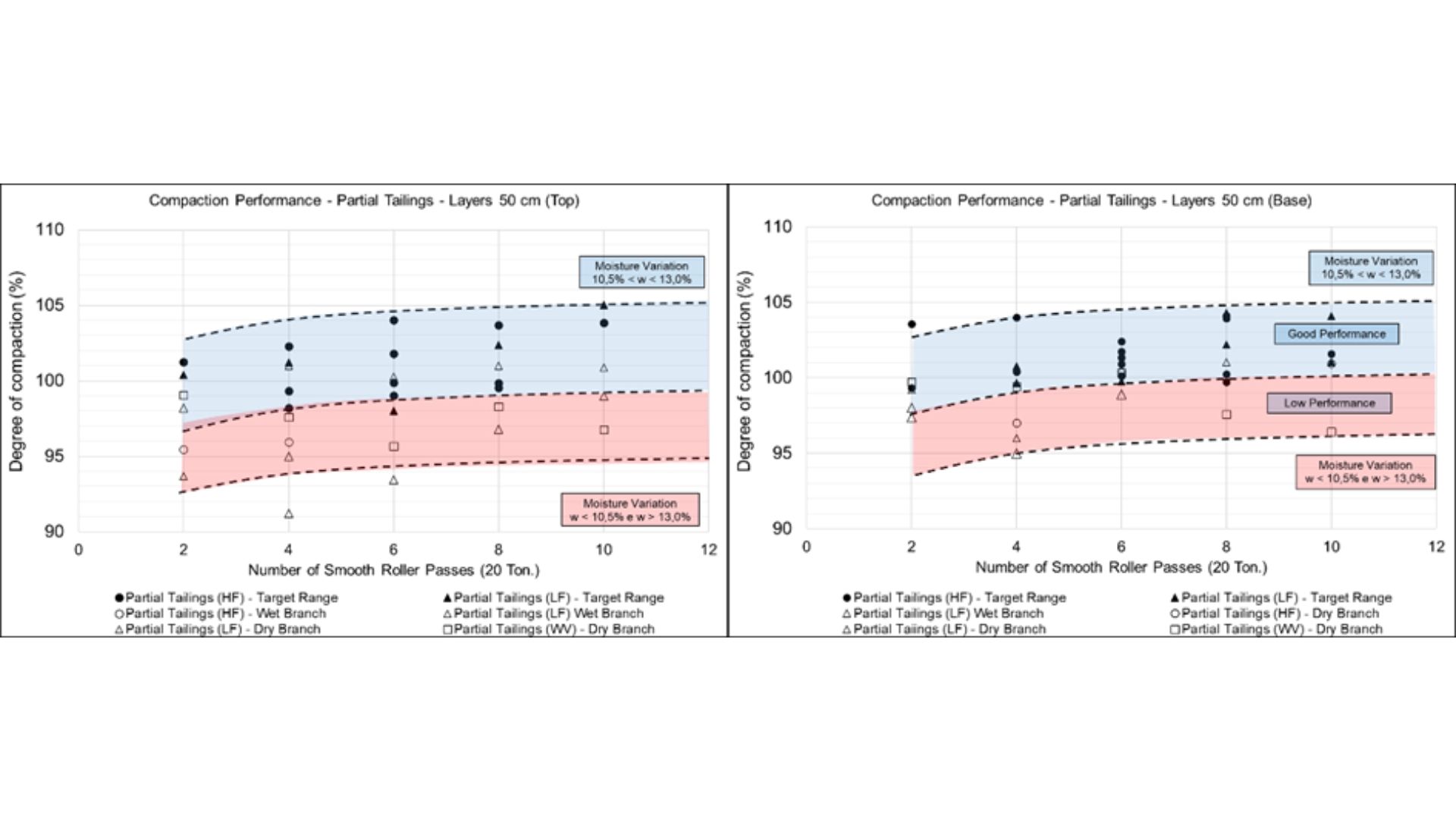

In Figures 6a, b, as well as in Figures 7a, b, the compaction performance is illustrated as a function of the number of passes for the 50 cm layers of both partial and total top/base tailings. It’s worth noting that layers above 50 cm did not exhibit satisfactory compaction performance due to challenges in achieving uniformity in thicker layers, achieving consistent moisture distribution top/base, and reducing compaction gradients. Hence, this study will primarily focus on analyzing the performance of the 50 cm layers. Figure 6: Compaction performance partial tailings top (a) and bottom (b)

Figure 6: Compaction performance partial tailings top (a) and bottom (b)

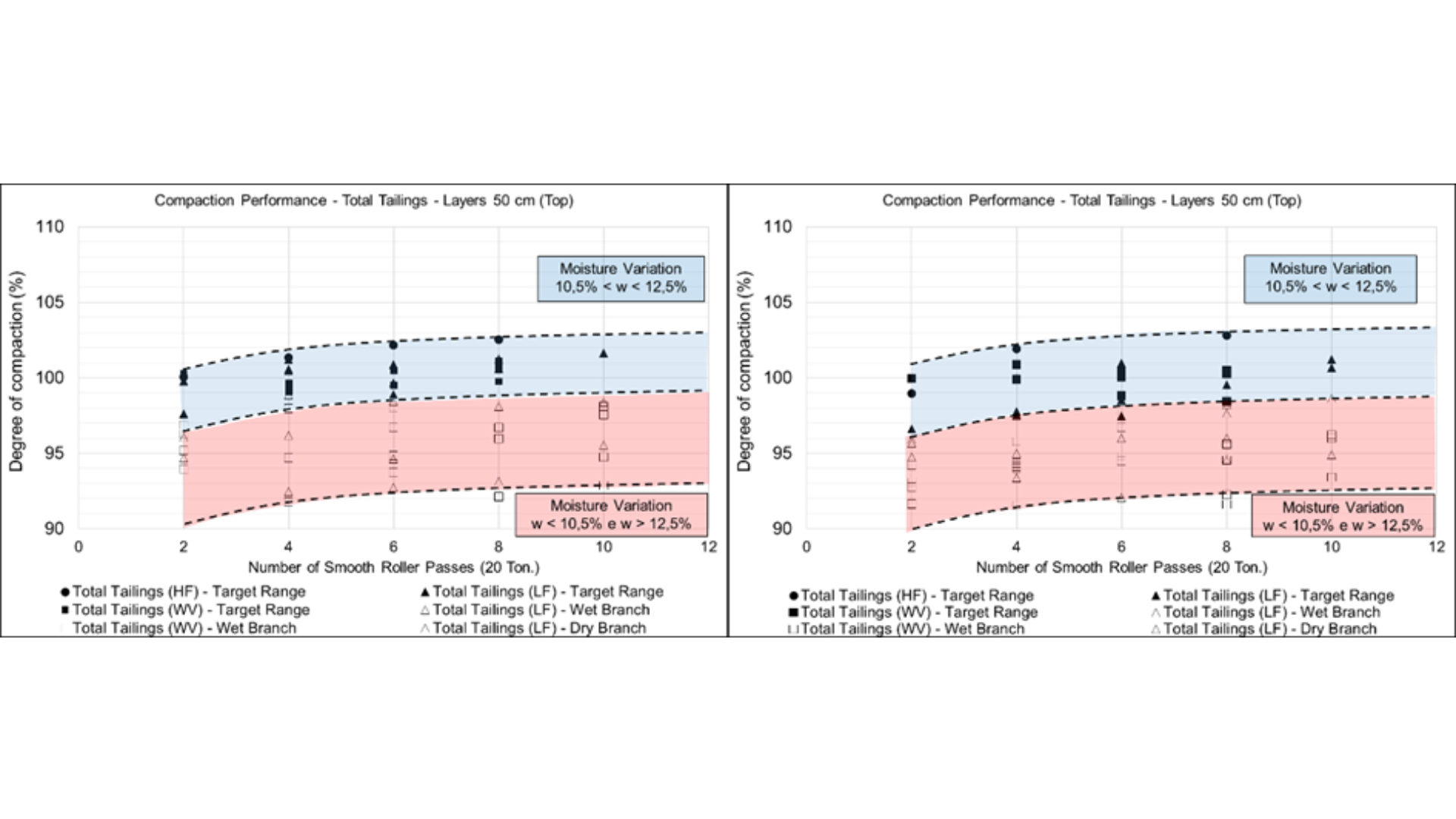

Figure 7: Compaction performance total tailings top (a) and base (b)

With regard to in situ performance, with variations in compaction energy, number of passes and humidity, the following points can be seen from the analysis of Figures 6 and 7 as a function of the energies applied and compaction humidity ranges:

- Partial and Total Tailings: Compaction degrees exceeding 95% were achieved after 2 passes, and over 98% after 4 passes using the 20-ton smooth roller at both low and high vibration frequencies. This was achieved for compacted layers within the optimal moisture range (between 10.5% and 13.0% for partial tailings, and between 10.5% and 12.5% for total tailings).

- Total Tailings: Sensitivity in the rubberized behavior was observed starting from a moisture content of 12.5%.

- Base Case Tailings: Moisture controls ranging from 10.5% to 12.5%, implemented after 4 passes, aimed to ensure uniformity at the top and base of the layer. This addresses potential moisture variations, operational fluctuations in compaction (roller speed), and potential discrepancies in technological control assays.

In both cases, a notable performance decrease was observed for the compacted layers with moisture content below 10.5% (dry branch) or above 12.5% to 13.0% (wet branch), with degrees of compaction falling below 95%. These findings underscore the necessity of moisture control near the optimum level, as under this condition, all tests involving passes of the 20-ton smooth roller exhibited satisfactory compaction performance.

Compaction performance as a function of in situ dry density

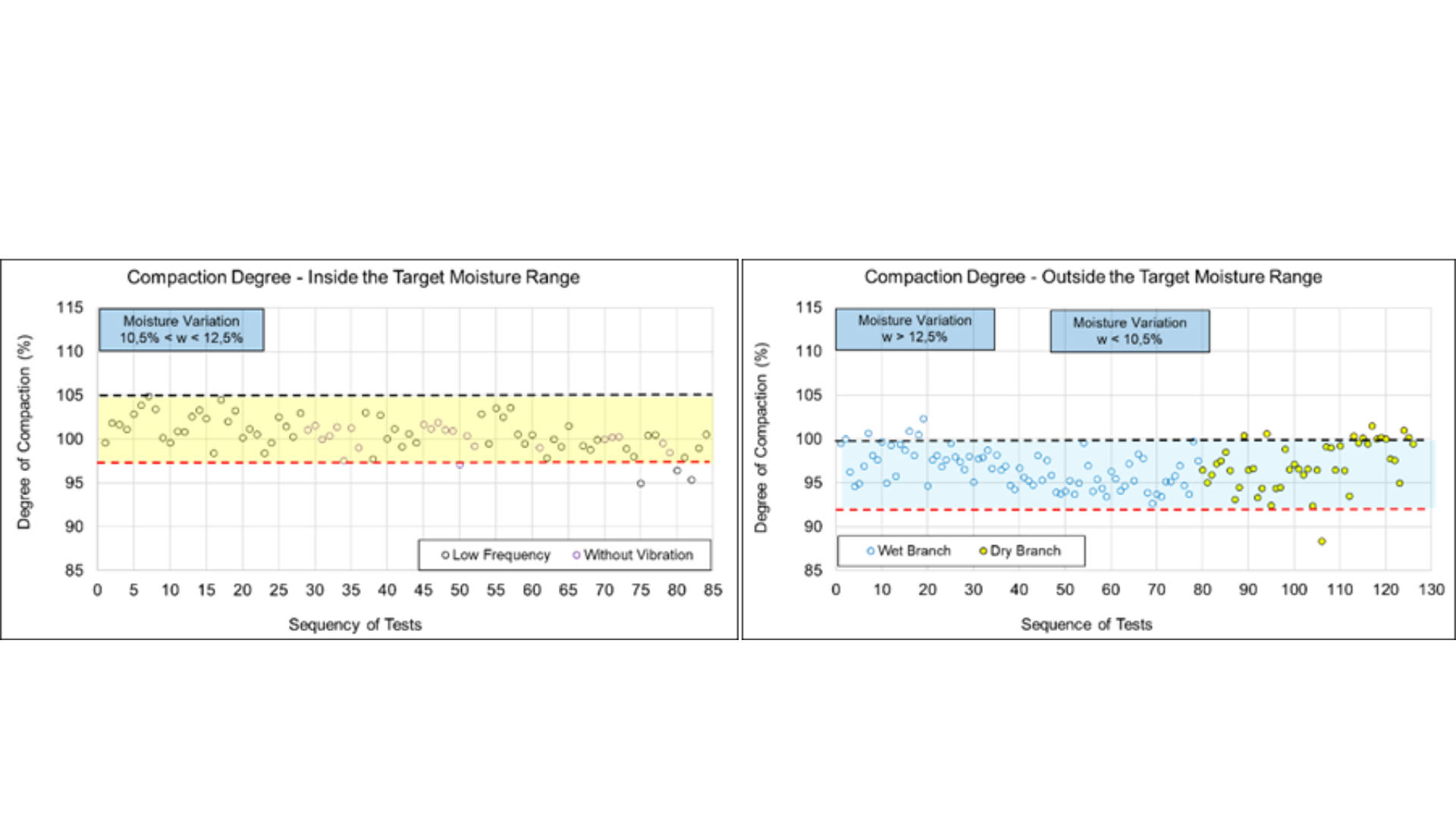

Figures 8a, b shows the overall distribution of compaction degrees for the tailings of the Base Case within the target moisture range (between 10.5% and 12.5%) and in the wet regime (above 12.5%). Figure 8: Degree of compaction Base Case tailings within the target moisture range (a) and outside the target moisture range (b)

Figure 8: Degree of compaction Base Case tailings within the target moisture range (a) and outside the target moisture range (b)

In general, for compacted layers up to 50 cm thick using the 20-ton roller, compaction degrees (C.D) ranging from 100 to 105% are observed within the compaction moisture range of 10.5% to 12.5%. In the total tailing’s material outside the target range, with moisture content in the wet regime, a rubbery behavior and water exudation on the surface were observed. Compaction degrees above 95% were noted, exhibiting a rubbery behavior that does not align with the macroscopic field response.

It was observed that, in this case, the compaction energy from the 20-ton roller after 2 passes was close to the intermediate energy range, resulting in compaction degrees above of 95% when using the Standard Proctor reference for layers exhibiting rubbery effects. The main focal points in the standardized compaction controls, based on the observed Hilf and Proctor tests, were as follows:

- Stringency in the timing of collecting the beveled samples, which should be done immediately after compaction, to avoid differences in wet density and moisture deviation between the moment of compaction and sample collection.

- Attention to the dispersion of results from the Standard Proctor tests compared to routine tests using the Hilf method.

- There will be outcomes with compaction degrees close to 100% in layers displaying rubbery behavior and dry densities below the minimum required.

- There will be results with compaction degrees above 100% in layers compacted within the Target Moisture Range.

- Greater uncertainty regarding the results and acceptance of compaction variations due to the variables presented, such as excessive compaction tests using the Hilf Method, routine repetitions, and changes in operators.

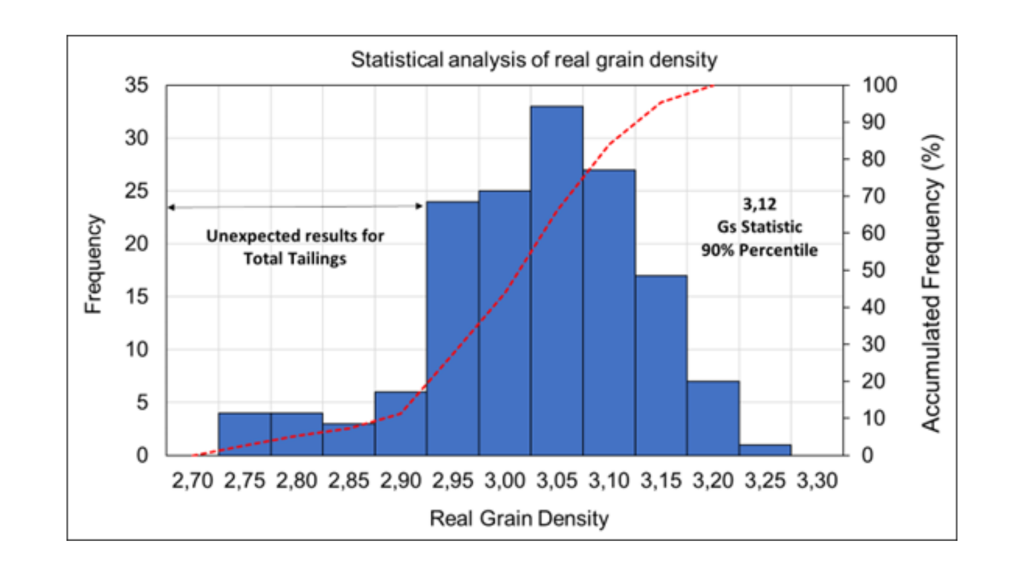

In this context, aiming to mitigate the uncertainties in compaction test routines, the technological monitoring of compacted layers in the experimental landfill was assessed using post-compaction dry density (γdmin). The minimum threshold for dry density (1.95 g/cm³) was established based on statistical analysis of the actual densities of tailings grains generated by the Plants (90th Percentile – 3.12) and the reference void ratio (0.60). Figure 9 displays the frequency distribution histogram of the obtained specific gravity.

Figure 9: Frequency histogram Real Grain Density

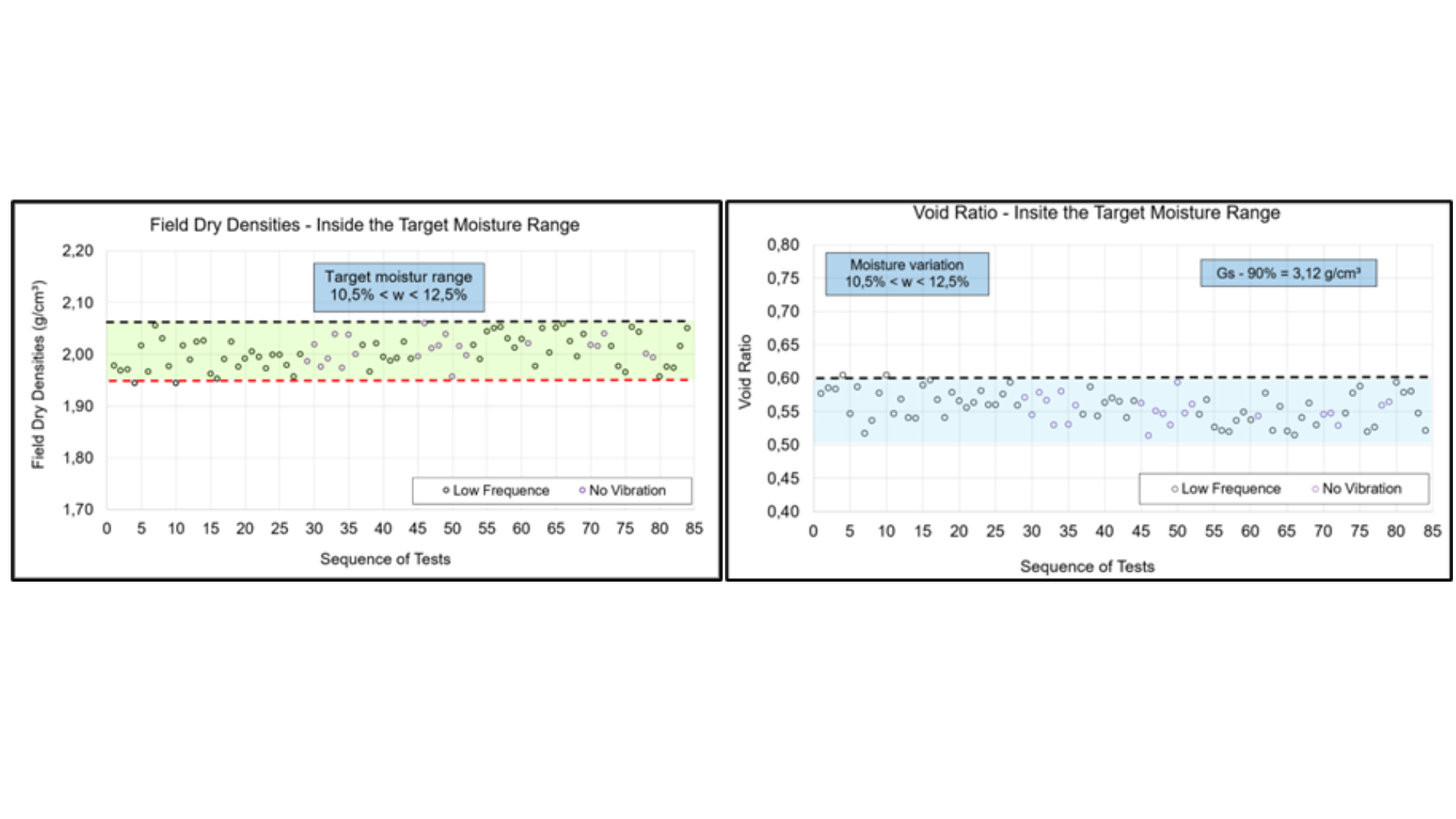

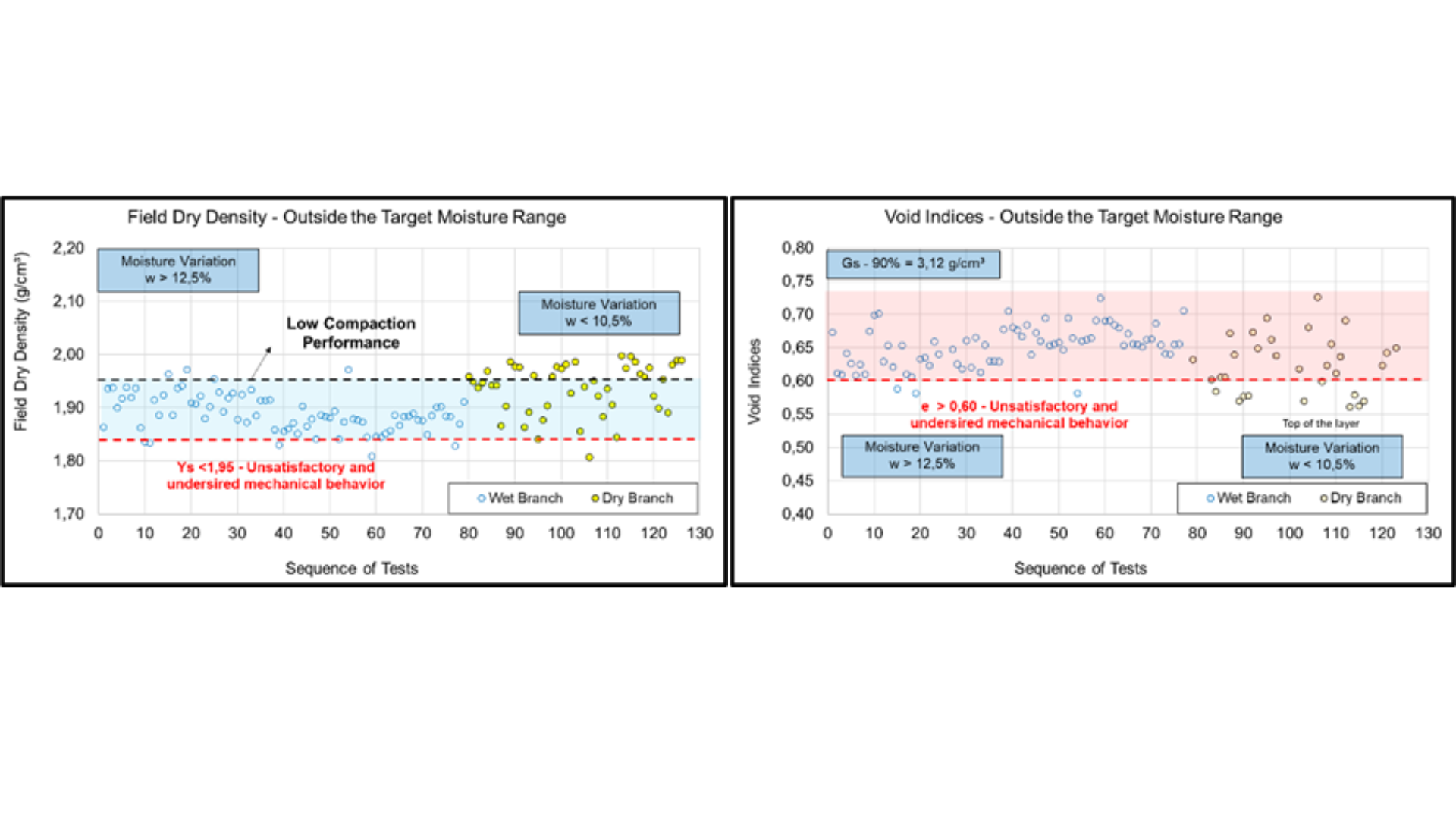

Figures 10a, b as well as Figures 11a, b depicts the controls of dry density and void ratios obtained in the layers of the experimental landfill for the base case tailings compacted within the moisture target range and outside these limits. Figure 10: Field Dry Densities (a) and Index of Voids (b) – Within the Moisture Target

Figure 10: Field Dry Densities (a) and Index of Voids (b) – Within the Moisture Target Figure 11: Field Dry Densities (a) and Void Indices (b) – Outside the Moisture Target

Figure 11: Field Dry Densities (a) and Void Indices (b) – Outside the Moisture Target

It is observed that the dry densities of the layers compacted within the moisture target thresholds (10.5% to 12.5%), exhibiting satisfactory behavior (void ratio below 0.60), exceeded the established statistical minimum threshold of 1.95 g/cm³. Conversely, for layers compacted outside the moisture target range (w < 10.5% or w > 12.5%), void ratios above 0.60 and dry densities below 1.95 g/cm³ were observed, reflecting the loss of mechanical performance in those layers.

It can be observed that the compaction control based on dry density exhibits strong representativeness and reliability compared to the Hilf and Proctor compaction control. Furthermore, the proposed approach of controlling by dry density eliminates the need for numerous Hilf/Proctor compaction tests during the tailing’s storage facilities (T.S.F) operation, thereby reducing uncertainties within the approval process flow.

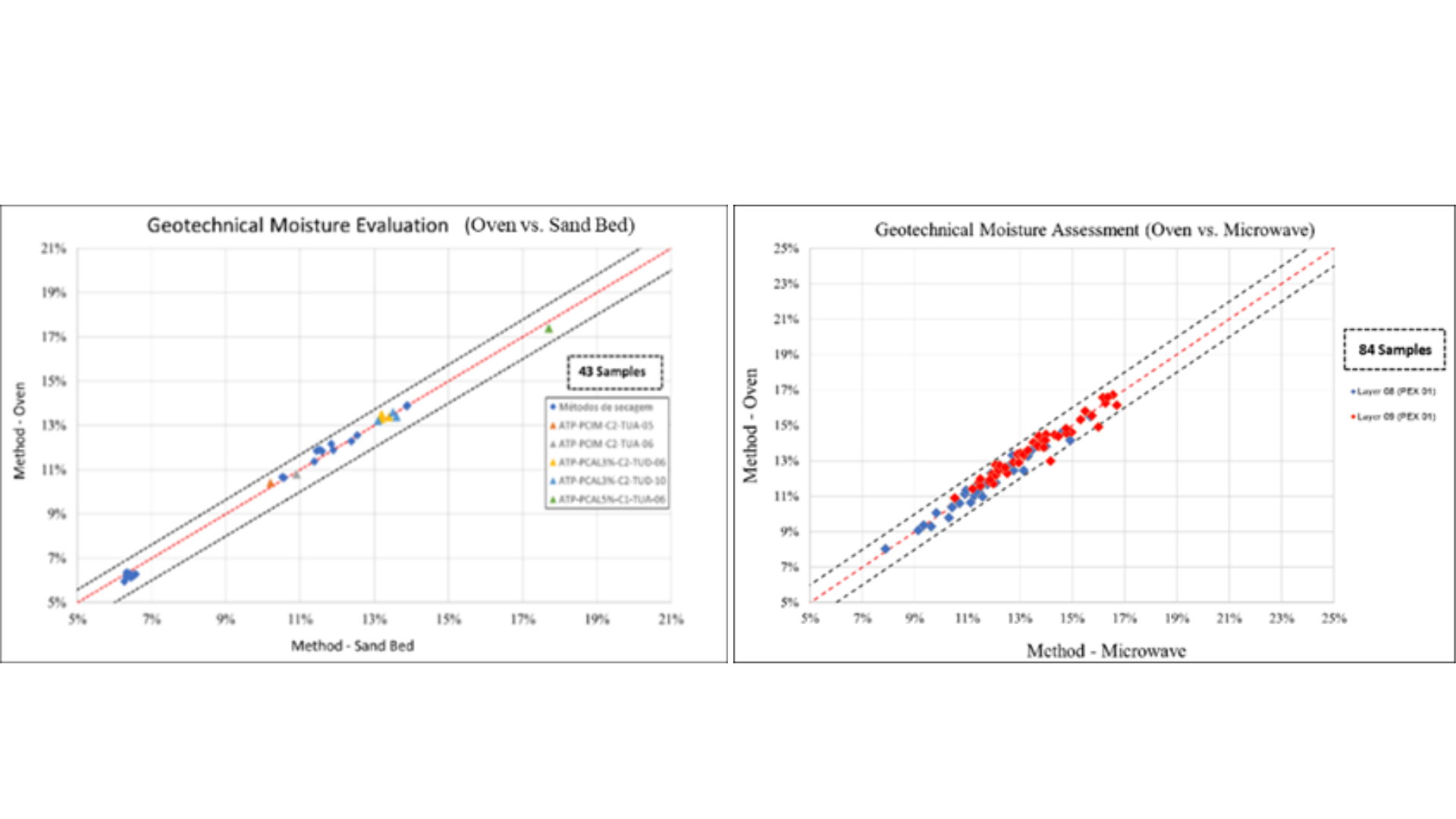

The control of minimum in-situ dry density can be carried out by collecting the cylinder and using a high-precision scale for weighing, along with moisture determination through methods like the sand bath or microwave techniques. These methods have demonstrated results with lower dispersion and greater convergence compared to moisture measurements taken in an oven within a timeframe of approximately 30 minutes (Fig.12a, b). Figure 12: Tests for moisture measurement: Sand cushion (a) and microwave (b).

Figure 12: Tests for moisture measurement: Sand cushion (a) and microwave (b).

Conclusion

In this study, the objective was to assess the compaction performance of mixtures consisting of sandy and ultrafine tailings (partial and total tailings) in proportions of 90/10 and 80/20, within the optimal moisture range, both in the dry and wet regimes. This assessment was conducted at varying compaction energies and layer thicknesses.

In a general, satisfactory compaction performance was observed for 50 cm layers within the moisture range of 10.5% to 12.5%. For the wet regime (w > 12.5%), rubbery effects and water exudation were observed. However, when monitored using Hilf and Standard Proctor tests, compaction degrees above 95% were noted even for layers displaying rubbery behavior, in which compaction energy is transferred to the air and water system.

Given the variability of tailings produced on an industrial scale, influenced by mining fronts or filtration processes, as well as potential variations in Hilf tests during continuous execution, a statistical treatment of actual grain densities (P90) was performed. Using a reference void ratio, a minimum dry density value was established for monitoring the disposal of tailings.

It was observed that monitoring through statistical dry density obviates the need for multiple Hilf compaction tests, reducing uncertainties within the approval process flow. Additionally, it adequately represents the targeted compaction performance focusing on void ratios, always on the dilatant side, with a saturation degree below 80%. For this monitoring approach, it’s recommended to continually update the statistical specific gravity through routine tests, reflecting possible variations in tailings production throughout the operation of the PDRs.

In summary, for monitoring the operation of tailings storage facilities, the following measurements can be carried out:

- Evaluation of tailings granulometries according to the Base Case thresholds;

- Target Moisture Range in accordance with the Base Case thresholds;

- Absence of “borrachudo” and Laminations;

- Statistical Minimum Dry Density and Maximum Void Ratio;

- Saturation Degree below 80%.

Acknowledgements

Special thanks to the team at BVP Geotechnics and Hydrogeotechnics, alongside the technical team from Vale’s experimental landfill area, for their support during the development of experimental studies on filtered tailings. The results presented in this study have expanded our understanding of the compaction and mechanical behavior of filtered tailings mixtures.

Authors

Antônio Freire, BVP Engenharia, Brasil

Washington Pirete, BVP Engenharia, Brasil

Paulo Cella, BVP Engenharia, Brasil

Diego Silva, BVP Engenharia, Brasil

Pedro Andrade, BVP Engenharia, Brasil

Alysson Oliveira, BVP Engenharia, Brasil

Ana Rissoli, Vale S.A, Brasil

References

Araújo, C.B. 2006. Contribuição ao estudo do comportamento de barragens de rejeito de mineração de ferro. Universidade Federal do Rio de Janeiro. Dissertação de Mestrado em Engenharia Civil. Rio de Janeiro. Disponível em: <http://www.coc.ufrj.br/index>. Acessado em: 04/10/2023

Associação Brasileira de Normas Técnicas. NBR 7181. 2016: Análise granulométrica. Rio de Janeiro, p. 12. 2016.

Associação Brasileira de Normas Técnicas. NBR 7182: Ensaio de Compactação. Rio de Janeiro, p. 09. 2020.

Associação Brasileira de Normas Técnicas. NBR 9813: Solo – Determinação da massa específica aparente in situ, com emprego de cilindro de cravação. Rio de Janeiro, p. 05. 2016.

Associação Brasileira de Normas Técnicas. NBR 12102: Solo – Controle de compactação pelo método de Hilf. Rio de Janeiro, p. 21. 2020.

BVP Engenharia e Hidrotecnia. 2023. Relatório Final Aterros Experimentais. p. 429.

Ghose, M.K. and sen, P.K. 2001. Characteristics of iron ore tailing slime in India and its test for required pond size. Environmental Monitoring and Assessment. v.68, p.51-61.

Srivastava, M.P., Pan, S.K., Prasad, N., Mishra, B.K. 2001. Characterization and processing of iron ore fines of Kiriburu deposit of Índia. International Journal of Mineral Processing. v.61, p. 93-107.